// OEM, ODM

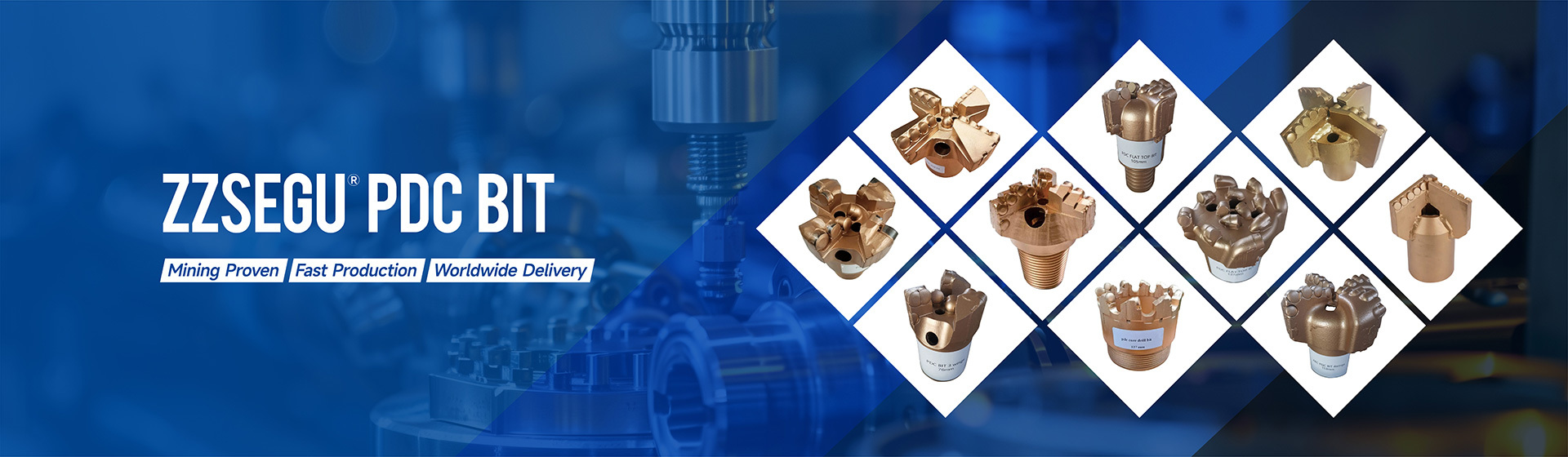

Focus on the production and development of mining machinery and equipment, PDC drill bits

Zhengzhou Sungood New Material Technology Co., Ltd. has 15 years of professional production of well drilling machine, PDC bits, PDC cutters, the engine filter , and so on. with 10,000 ㎡ of plant, products are sold to the Americas, Europe, the Middle East, Southeast Asia, Russia and other regions and countries. We can complete all kinds of customized products. Welcome to discuss cooperation with us.

// PRODUCT SERIES

CHOOSE OUR PRODUCTS

Including PDC arc bit, PDC concave bit, PDC core bit, PDC flat top bit, PDC drag bit, PDC anchor bit, and so on.

Including steel tooth tricone bit, insert tooth tricone bit, TCI Tricone Bit, IADC 127, IADC 237, IADC 537, IADC 637, etc

Petroleum PDC bits are designed with 4 wings, 5 wings, 6 wings and 7 wings, and comply with SY/T5164 and API Spec7-1 standards. PDC Cutters adopt the 16/19 series.

Including 1005/1205/1304/1305 / 1308/ 1608/1613/1616/1910/1913,etc. And Custom PDC CUTTERS.

Including geological exploration drill machine, electric hydraulic drill rig, Mud pump - Pneumatic multi-functional DTH water well drilling machine, etc

Detection instruments and equipment

Detection instruments and equipment

Including Groundwater Detector, mineral detector, metal detector, archaeological detector, etc.

// PRODUCT

HOT-SELLING PRODUCTS

Factory sales 113mm Arc PDC Drill Bit for Mining PDC Bits for well drilling sumur bor

SUNGOOD TECH 7 1/2inch IADC 537 Tricone Drill Bit Rock Bit

Factory 200 meters Mud Pump and Air Compressor Dual Diesel Hydraulic Water Well Drill machine

Intelligent High-density Groundwater Detector 3000-Meter Precision Exploration

CUSTOMER REVIEWS

1600WT4 Positive review

// WHY CHOOSE OUR COMPANY

SOME REASON FOR CHOOSEOUR COMPANY

Manufacturer strength

With more than 15 years of industry experience, standardized production workshop, complete production testing equipment, mature technology

Equipment quality

Every product from raw materials to shipment, almost every production process will go through strict quality testing to ensure quality

Price advantage

We are the entity manufacturer, R & D production, sales, installation after-sales one-stop service, no middlemen, low prices

After sale, Worry Free

Has a perfect pre-sales and after-sales service system, the whole 1 to 1 service, to provide installation and technical support, after-sales rest assured

// BLOG & FAQ

Technical Services

Dive into the World of Varel PDC Bits: Innovations and Insights

Explore the latest trends and advancements in Varel PDC bits for drilling.

Jan 27,2026

A PDC matrix bit drills formations using diamond cutters on a tungsten carbide body. Gage protection maintains hole diameter. PDC gage offers superior abrasion resistance for uniform rock, while alloy rings provide better impact resistance in interbedded layers. The choice critically affects bit life and drilling cost.

Jan 25,2026

How Does Diamond Grit Quality Affect the Performance of Diamond Core Bits?

The performance of electroplated diamond core bits is fundamentally determined by the quality of the diamond grit (diamond abrasive) used. Key factors such as diamond strength, thermal stability, mesh size, concentration, crystal shape, and surface coating directly dictate drilling efficiency, bit longevity, and overall cost-effectiveness.

Jan 20,2026