Product Overview

Excellent performance

1.High density (low porosity)

2.High uniformity of composition and structure

3.Excellent adhesion between diamond particles

4.High wear resistance

5.High impact resistance

6.High thermal stability

7.Optimized interface between diamond and tungsten carbide layer for excellent bonding

Diamond composite sheets are made by sintering diamond micropowders with a hard alloy matrix under ultra-high pressure and temperature. They possess the high hardness, wear resistance, thermal conductivity of diamond, as well as the strength and impact resistance of hard alloy. They are ideal materials for manufacturing cutting tools, drilling bits, and other wear-resistant tools. It has been widely used in industries such as oil drilling, geological exploration, coal mining drill bits, and mechanical processing tools.

Advantages of PDC cutter

PDC (Polycrystalline Diamond Compact) cutting tools are composed of synthetic diamond and tungsten carbide under high temperature and pressure. It will combine the advantages of diamond and tungsten carbide, and have high wear resistance, high impact resistance, and high thermal stability.

FEATURES AT A GLANCE

1.The PDC cutter of two adhesive components - polycrystalline diamond composite sheet itself and tungsten carbide substrate.

2.As the matrix material of PCD, hard alloy not only has good toughness and certain hardness, but also has high impact strength, weldability, machinability, and compatibility with PCD.

3.The size of polycrystalline diamond composite sheets can be enlarged, and through laser cutting, they can be made into specific shapes to meet the requirements of different tools.

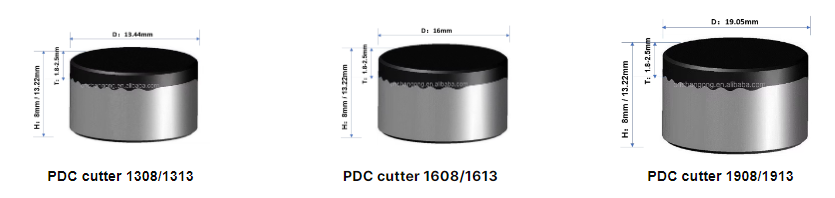

PRODUCT SPECIFICATIONS

Product Specification Data Reference

PCD cutters come in different specifications and sizes. Please choose the appropriate PCD cutter based on the type of drill bit and working environment. Please provide the following important information for our engineers' reference:

1. Type of drilling conditions (coal mining, geological drilling, quarries, etc.).

2. Formation type and hardness.

3. Drilling depth requirements.

4. Special design precise drawings.

|

Specification |

Diameter |

High |

Diamond layer |

Diamond chamfer |

Hard alloy chamfering |

|

pdc1005 |

10mm |

5mm |

1.8-2.5mm |

0.3mm×45° |

0.5mm×45° |

|

pdc1304 |

13.3mm |

4.5mm |

2.0-2 2mm |

0.3mm×45° |

0.5mm×45° |

|

pdc1308 |

13.44mm |

8.00mm |

1.8-2.5mm |

0.3mm×45° |

0.5mm×45° |

|

pdc1313 |

13.44mm |

13.20mm |

1.8-2.5mm |

0.3mm×45° |

0.5mm×45° |

|

pdc1608 |

16.00mm |

8.00mm |

1.8-2.5mm |

0.3mm×45° |

0.5mm×45* |

|

pdc1613 |

16.00mm |

13.20mm |

1.8-2.5mm |

0.3mm×45° |

0.5mm×45° |

|

pdc1908 |

19.05mm |

8.00mm |

1.8-2.5mm |

0.3mm×45° |

0.5mm×45° |

|

pdc1913 |

19.05mm |

13.20mm |

1.8-2.5mm |

0.3mm×45° |

0.5mm×45° |

|

pdc1925 |

19.05mm |

25.00mm |

2.0-2.5mm |

0.3mm×45° |

0.5mm×45° |

PRODUCT CONFIGURATION

Drilling and mining of PDC cutter

Suitable for drilling in soft and medium hard geological conditions with high impact toughness and thermal stability. High temperature resistance up to 750 ℃ (2 minutes), this product can be combined with flat and various groove shapes, and groove shapes can be designed, ground, products with special shapes, polished, chamfered, etc. according to user needs.

Why did you choose us?

Zhengzhou Sungood New Material Technology Co., Ltd. has 15 years of professional experience in the production of mining machinery mining tools and accessories. Its main products include PDC cutting tools, PDC drill bits, diamond drill bits, etc. Our products are sold to multiple countries and regions, and we have established stable cooperative relationships with more than 20 customers worldwide.

What can we offer you?

Zhengzhou Sungood New Material Technology Co., Ltd. has been developing new products mainly based on diamond composite materials and efficiently producing the following drilling tools:

※ PDC cutting tools/blades: 1304, 1305, 1306, 1308, 1310, 1313, 1613, 1616, 1913... petroleum or mining types. ※ PDC core drill bits: diameter 46mm, 50mm, 55mm, 60mm, 65mm, 75mm, 89mm, 94mm, 98mm,113mm, 124mm, 127mm, 132mm, 146mm, 153mm, 190mm, 216mm,.......

※ PDC non core drill bits: including arc angle drill bits, flat top

drill bits, and concave drill bits, providing products of any size from 50mm to 300mm. According to your needs, you can produce products such as two wings, three wings, and four wings; PDC anchor rods for roof bolt support: diameter 25mm, 27mm, 28mm, 29mm, 30mm, 32mm, 35mm, 42mm, 43mm Hard alloy drill bits: double wing coal drill bits, chisel drill bits, cross drill bits, button drill bits, hammer heads According to your needs, we can provide you with customized products, including trademarks, packaging, etc

PACKAGING AND DELIVERY

Single carton box package, safe and regular placement.

Samples are shipped by express, batch products are shipped by sea or by air.

Delivery: 1-5 days for samples, 1-15 days for batch products.

Keywords

Factory 1308 High-end Convex PDC Cutters Diamond Inserts

Classification:

Related Products

There is no relevant data for the time being, please add it backstage!