Nov 03,2025

XY-1 Core Drill: A Comprehensive Review of Its Features and Specifications Meta

Explore the XY-1 core drill, a versatile and reliable diamond drilling rig. This guide covers its key features, full technical specifications, and applications in mineral exploration and geotechnical drilling.

Oct 20,2025

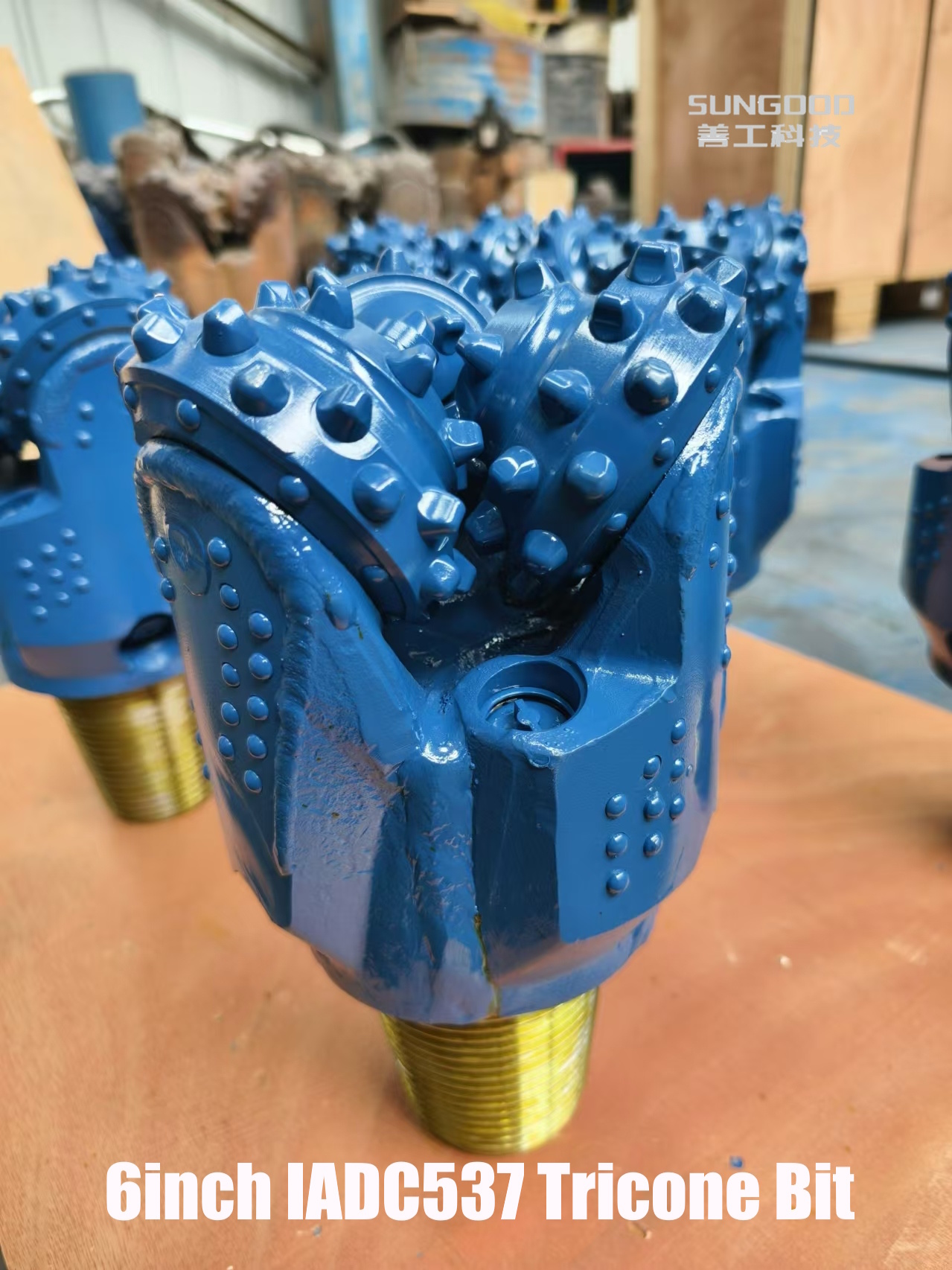

Optimizing Drill Bit Selection for Challenging Cobble Formations

Choosing the right drill bit is critical for efficient drilling in abrasive and unstable cobble layers. This article compares the applicability of (tricone bit) roller cone bits, PDC bits, and DTH hammer bits for this challenging formation.

Oct 17,2025

The 90A Hammer: A Classic in Low-Pressure DTH Drilling

In rock drilling fields such as mining and hydraulic engineering, the Down-The-Hole (DTH) hammer is the core power source. This article focuses on the Atlas Copco COP 90A series hammer, providing an in-depth analysis of its technical positioning as a low-air-pressure hammer.

Oct 14,2025

DTH Hammer Casing Bit: Technology, Application, and Key Considerations

A DTH hammer casing bit is a specialized drilling tool used in complex strata such as in geotechnical and mountain drilling. Its primary function is to prevent borehole wall collapse or sand influx during the drilling process.

Oct 10,2025

DTH Casing Bit: Structure, Functions and Application Scenarios

This paper focuses on the DTH (Down-the-Hole) casing bit in DTH drilling tools, systematically expounds its unique structural characteristics, deeply analyzes its core functions, and lists typical application scenarios in combination with actual engineering needs.

Oct 07,2025

Back Hammer: Principle and Application in Drilling Engineering

The Back Hammer is a specialized downhole tool powered by high-pressure air, designed to deliver high-frequency impact forces for solving specific drilling challenges. This article details its pneumatic operating principle, key structural features, and unique application value, particularly in operations such as casing pulling.

Oct 02,2025

How Does a DTH Drill Bit's Button Design Change for Different Rock Types?

The performance and lifespan of a Down-The-Hole (DTH) hammer bit are critically determined by the design of its tungsten carbide buttons. This article details how button material, shape (or geometry), and layout are precisely engineered to match specific rock conditions, from soft and abrasive to extremely hard and massive formations.

Sep 26,2025

DTH Drilling: What's the Difference Between Eccentric and Center Bits?

Think of the Center Bit as the precise guide that sets the path, and the Eccentric Bit as the powerful reamer that makes room for the protective casing. Together, they enable fast and secure drilling in the most challenging conditions.

Sep 24,2025

Soaring Alloy Raw Material Prices: Impact on PDC and Tooling Production

This article analyzes the rapid rise in alloy raw material costs in 2024-2025, focusing on the mounting pressure on downstream manufacturers of PDC cutters, PDC bits, and alloy tools, while exploring future price trends.

Sep 15,2025

Which Gage Protection Is Right for Your Drill Bit?

This article explores the critical choice between Tungsten Carbide pads and PDC cutters for bit gage protection. It breaks down their working principles, pros, cons, and provides a clear selection guide based on formation abrasiveness and drilling objectives to optimize performance and longevity.

Contact Us