Jul 15,2025

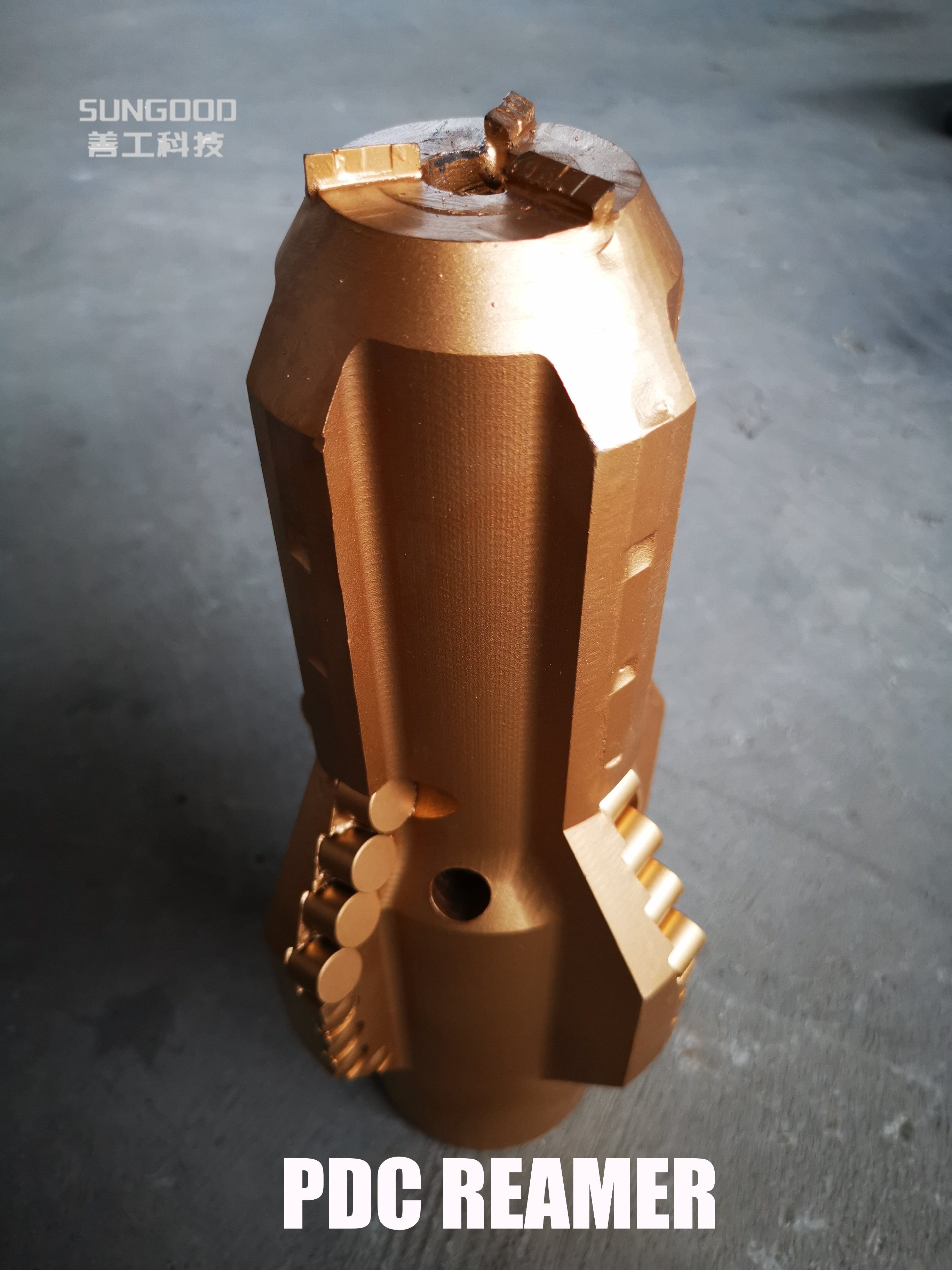

Undersized Wellbore? How PDC Reamers Deliver Precision Solutions

PDC reamers critically enlarge wellbores to target specifications, ensuring seamless casing runs, robust cementing, and advanced completion readiness. Their engineered durability maximizes drilling efficiency and operational safety.

Jul 08,2025

Which PDC Bit Conquers Your Geology? SUNGOOD TECH Has the Answer

Choosing the right PDC drill bit (blade, conical, concave, flat-top) based on rock type, hardness, abrasiveness, and layer consistency is critical for efficient and cost-effective water well drilling. Matching the bit design to the specific geological formation optimizes penetration rates and bit life.

Jul 02,2025

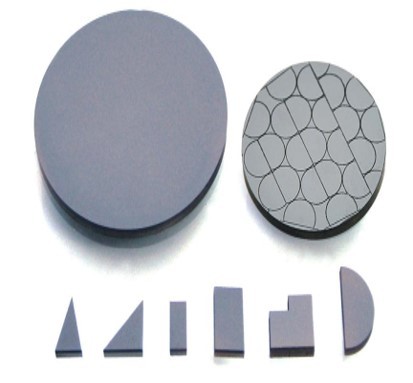

Drill Bit Cutters: Tungsten Carbide or PDC?

Selecting drill bit cutters directly impacts efficiency and cost in complex formations. How to balance tungsten carbide’s impact resistance and PDC’s cutting sharpness? Hybrid designs now unlock breakthrough performance.

Jun 30,2025

Don’t Let Thread Confusion Cost You Millions

A single mismatched thread can trigger a $500k drilling rig shutdown. While global thread standards like Metric (M), Unified (UNC/UNF), and British Pipe (BSP) dominate machinery, critical nuances in taper angles, pitch, and sealing methods dictate success in extreme environments – especially for PDC bits and downhole tools.

Jun 27,2025

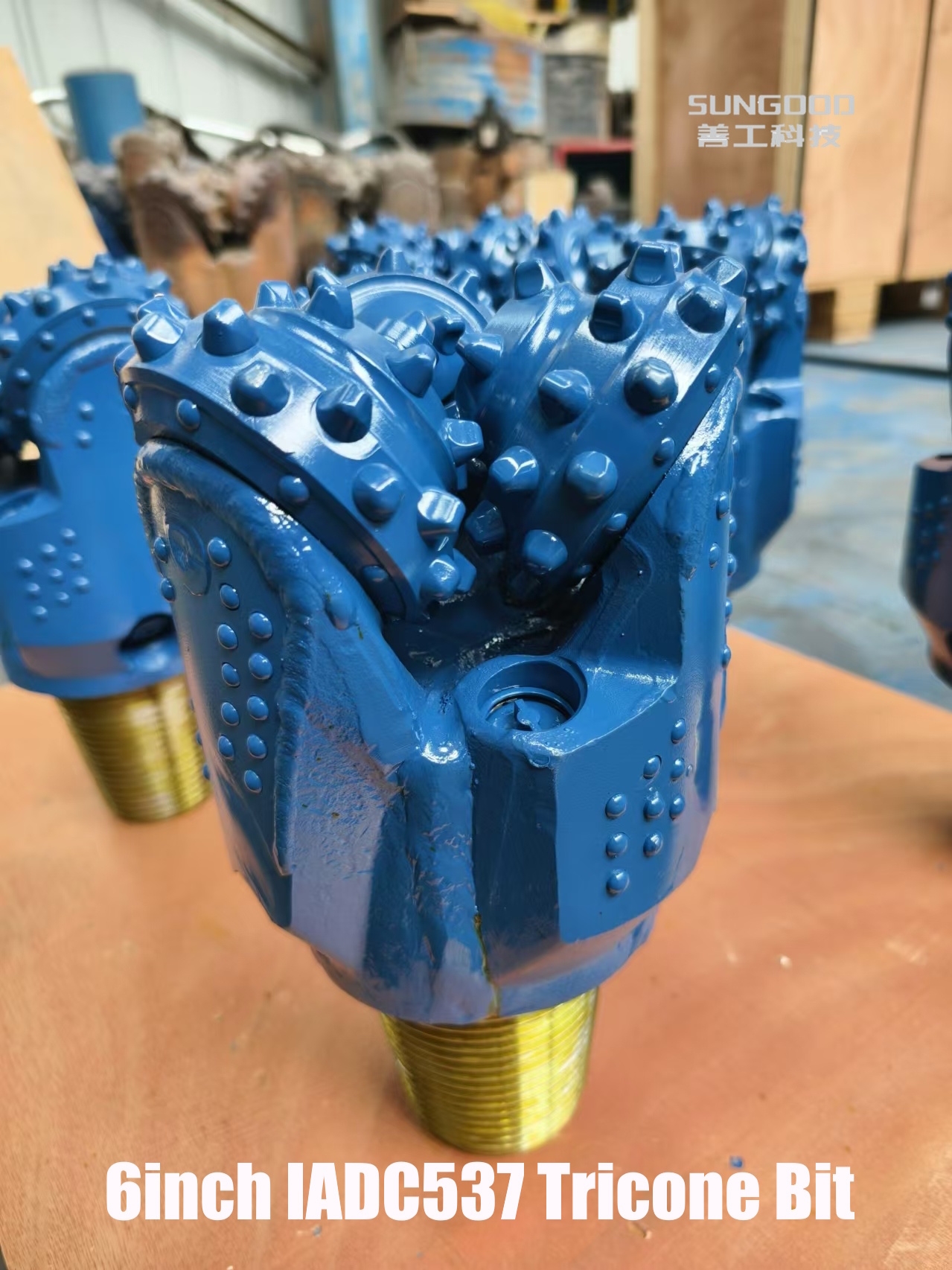

What Does IADC537 Mean for Tricone Bit Selection?

Decode the IADC537 drill bit classification: its meaning (insert bit for medium-soft formations with hard stringers), optimal application conditions, and key alternatives. Learn how SUNGOOG TECH leverages IADC coding for efficient drilling solutions.

Jun 25,2025

How to Select Tricone Bits Based on Geological Conditions: Unlock Efficient Drilling

Selecting tricone drill bits requires matching geological formation characteristics: soft rock favors milled tooth bits; hard/abrasive formations need TCI bits with reinforced gauge protection; HP/HT wells require metal-sealed bearings.

Jun 23,2025

Nozzle or No Nozzle: Which PDC Bit Wins in Water Well Drilling?

Discover how nozzle technology of PDC bit revolutionizes drilling efficiency by 200% with precision hydro-cutting.

Jun 20,2025

The Critical Role of Metal Nozzles in PDC Drill Bits for Oilfield Applications

In petroleum drilling operations, the performance of PDC (Polycrystalline Diamond Compact) drill bits directly dictates drilling efficiency and cost-effectiveness.

Jun 19,2025

What Are the Hidden Costs in Water Well Drilling?

Beyond visible steel, labor, and equipment expenses, water well drilling harbors significant hidden costs – often exceeding 20% of project budgets. These elusive expenses, stemming from inefficient decisions, mismatched technology, downtime, and compliance risks, silently erode profitability.

Jun 16,2025

PDC or Alloy bit? Which Coreless Bit Boosts Hydraulic Drilling Efficiency?

PDC or Alloy bit? Which Coreless Bit Boosts Hydraulic Drilling Efficiency? Rock composition, budget constraints, and project timelines dictate optimal selection.

Contact Us