Sep 10,2025

Rotary Screw vs. Piston Air Compressors: What's the Difference for Drilling Operations?

This article compares rotary screw and piston air compressors, highlighting key differences in performance, reliability, and efficiency, with a specific focus on their critical applications in demanding drilling operations.

Sep 08,2025

Why is a High-Pressure Air Compressor a Critical Equipment for Well Drilling Rigs?

The high-pressure air compressor for a well drilling machine is the core power source of modern rapid drilling technology. It provides high-pressure, large-volume compressed air to simultaneously power the impactor hammer and eject cuttings from the borehole, significantly improving drilling efficiency and depth.

Sep 05,2025

How Do Reverse Threads Elevate Mining & Oil Drill Bit Performance?

Reverse threads solve critical issues in mining and oil drilling—stuck pipe, torque imbalance, and tool failure. This article explores their key uses: preventing drill string loss in mining, boosting deep-well load capacity, balancing oil drilling torque, and expanding tool functions.

Aug 27,2025

What is the Center Column on a Mining Concave PDC Bit?

The center column is a fundamental design feature of mining concave PDC bits. These columns, protruding upwards within the bit's concave profile and armed with PDC cutters, are critical for enhancing stability, improving cuttings removal, increasing rock-breaking efficiency, and extending the bit's lifespan in challenging formations.

Aug 19,2025

Electroplated Diamond Core Bits vs. Roller Bits

Electroplated diamond drill bits fix diamond particles through an electroplating process, achieving an efficient integration of super-hard matrix and cutting units. Among them, the core bit ensures a sampling rate of over 95% in brittle rock layers, while the roller bit breaks through the bottleneck of drilling in hard rock with a pressure of over 150 MPa. Together, they address the core pain points in geological exploration and energy development.

Aug 06,2025

Unlocking Efficiency: The Power of Tri-Blade Alloy Stepped TCI Drag Bits

Tri-blade stepped TCI (Tungsten Carbide Insert) drag bits revolutionize drilling in heterogeneous formations.

Aug 01,2025

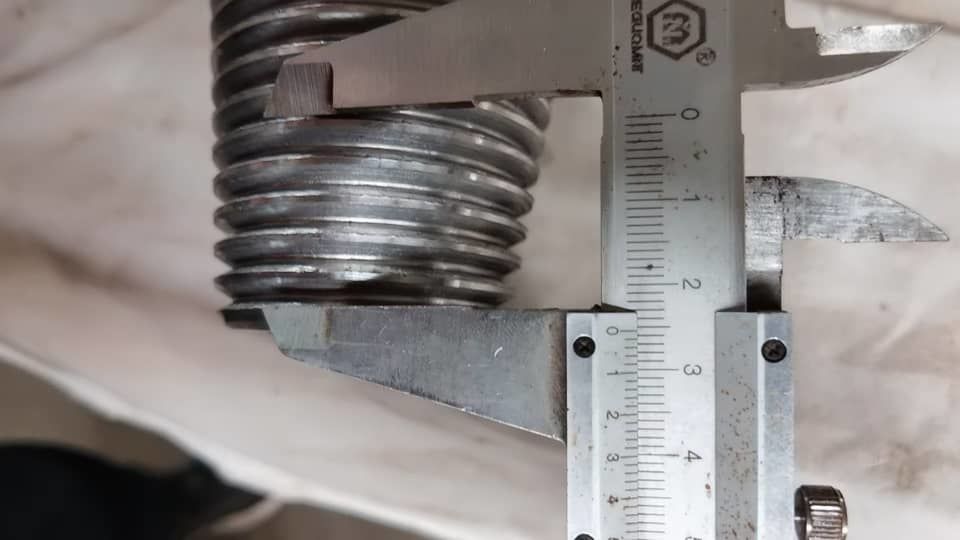

What is the Z50 Thread Commonly Used for Water Well Drill Bits and Drill Rods?

The Z50 thread is a specialized, high-strength connection designed for water well drilling equipment like drill bits and drill rods, offering superior torque resistance and reliability in demanding conditions.

Jul 31,2025

Battling PDC Bit Balling: Prevention and High-Efficiency Solutions

Bit balling in PDC drilling cuts ROP by 40–70%, induces well-control risks, and accelerates cutter wear. Key fixes: inhibitive drilling fluids (low-solids, KCl-enhanced), hydraulic optimization (flow rates >1.0 m/s annular velocity), and structured bit designs.

Jul 28,2025

PDC Stepped Drill Bits: Efficient Drilling for Water Wells and Mining

PDC stepped drill bits (polycrystalline diamond compact bits) feature a stepped cutting structure and high wear resistance, widely used in water wells, construction engineering, and mining.

Jul 25,2025

Features and Applications of Tower-Type Tungsten Carbide Alloy Tooth Water Well Drill Bits

SUNGOOD TECH's tower-type tungsten carbide alloy tooth drill bits feature multi-tiered structure design and WC-Co teeth, offering extended lifespan and high-precision boring for deep wells in hard rock formations.

Contact Us